Our team brings in the table our detailed knowledge in the regulatory framework, our vast experience on Ballast Water Sampling and Analysis for D-2 Discharge Standard, the deep understanding on vessels ballast operations and the operation of the Ballast Water Treatment Systems which together with our love for the sea and servicing reliably the Maritime sector, we trust it makes us the perfect partner for the Commissioning Testing of your newly installed BWMS.

Regulatory Background

Following entry into force, on 1st June 2022 [MEPC.325(75)] of the amendments to E-1 Regulation of the Ballast Water Management Convention, an initial survey is required before a ship is put in service or before the International Ballast Water management Certificate is issued for the first time. Among other, this survey shall confirm that a commissioning test has been conducted to validate the installation of any ballast water management system by demonstrating that its mechanical, physical, chemical and biological processes are working properly, taking into account the guidelines developed by IMO.

IMO developed the “2020 Guidance for the commissioning testing of ballast water management systems” and published in the Circular “BWM.2/Circ.70/Rev.1”, which is currently into force.

The following steps should be undertaken following installation of the BWMS on board the ship, and after all ballasting equipment (e.g. pumps and piping) has been fully installed and tested, as appropriate:

.1 a sample may be collected during ballast water uptake to characterize the ambient water, by any means practical (e.g. in-line sample port or direct harbour sample). Characterization of the ambient water does not require detailed analysis of the uptake water, however an indicative analysis may be undertaken;

.2 a representative sample should be collected during the corresponding ballast water discharge after the full treatment has been applied. Samples should be collected from the sampling point as described in the Guidelines on ballast water sampling (G2). The total sample volume should be at least 1 m3. If a smaller volume is validated to ensure representative sampling of organisms, it may be used;

.3 the representative samples should be analysed for the two size classes of organisms, namely ≥ 50 μm and ≥ 10 μm to < 50 μm, as specified in the D-2 standard, using indicative analysis methods listed in BWM.2/Circ.42/Rev.2, as may be amended; and

.4 the applicable self-monitoring parameters (e.g. flow rate, pressure, TRO concentration, UV transmittance/intensity, etc.) of the BWMS should also be assessed, taking into account the system design limitations of the BWMS, and the correct operation of all sensors and related equipment should be confirmed.

The commissioning test is successful if the indicative analysis indicates that the discharge samples do not exceed the D-2 standard for the size classes analysed (see paragraph 4.3) and the self-monitoring equipment indicates correct operation. Indicative analysis equipment used should be to the satisfaction of the Administration. Indicative analysis is defined in BWM.2/Circ.42/Rev.2, as may be amended.

According to IACS Procedural Requirements for Service Suppliers (Z17 Rev16 Aug 21), analysis of all organism type/size classes or combination of detail and indicative analysis can also be performed, (paragraph 18.5).

How we can assist

Our organization is an approved Service Supplier by multiple IACS members. We bear approvals from the American Bureau of Shipping (ABS, Bureau Veritas (BV) & Det Norske Veritas (DNV), LR, Nippon Kaiji Kyokai (Class NK) and Registro Italiano Navale (RINA).

We offer detailed analysis onboard the vessels for the size class of larger or equal to 50 um and a choice of indicative (PAM Fluorometry) or detailed (Epifluoresence Microscopy) for the size class of organisms with size between 10 and 50 um, offering to our clients quick (within 6 hrs) and undisputable reports without grey areas and uncertainty to the results.

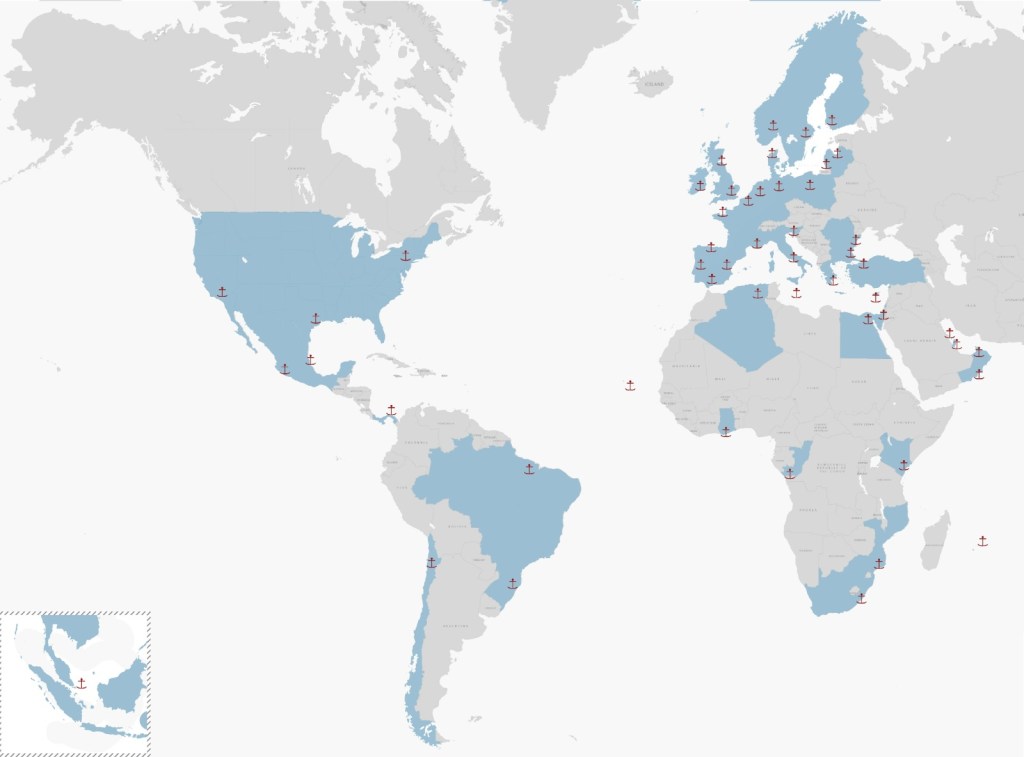

Where we operate

For Commissioning testing of Ballast Ststems with our teams based in Greece, Netherlands & Turkey we can cover whole Europe and Middle East.

We have the availability to serve our clients globally if required, as all our processes take place onboard with our mobile laboratories

Saron Marine PC

Kifissias Avenue 196,

145 62 Kifissia,

Athens

Greece

E: info@saronmarine.com

T: +30 2108080835

Saron Marine

Shanghai Co Ltd

Room 105, Building C3,

Lane 3188 Xiupu Road,

Pudong New District

Shanghai City,

China

Saron Marine BV

Planet B.io – Van Iterson Building

Alexander Fleminglaan 1

2613 AX Delft

The Netherlands

E: ara@saronmarine.com

T: +31 (0)152062424